Advanced Video Inspection Services

Our advanced video pipe inspection services use high-definition cameras to provide a crystal-clear, real-time view of the interior condition of your sewer and drain lines. Whether you’re dealing with recurring backups, slow drains, or planning a repair, this non-invasive diagnostic method allows us to detect hidden issues without guesswork or unnecessary digging. Ideal for both residential and commercial properties, our video inspections offer precision, speed, and peace of mind.

What Our Video Inspections Can Reveal

- Identify Damages: Detect cracks, offset joints, pipe corrosion, root intrusions, and other forms of structural damage before they lead to major failures or costly repairs.

- Locate Obstructions: Pinpoint the exact location of grease buildup, debris, foreign objects, or collapsed sections that are slowing or blocking flow through your pipeline.

- Assess Pipeline Integrity: Evaluate the overall health and longevity of your plumbing system, giving you a clear understanding of when maintenance or replacement may be needed.

Our sewer inspections use advanced HD camera technology to quickly diagnose issues, locate damage, and verify pipe conditions without digging.

It all starts with a sewer inspection- Let's look inside your sewer line

At Pipeliner Pros, we use high-tech camera systems to inspect your plumbing system and determine the integrity of your pipes. Whether you’re dealing with kitchen grease buildup or tree root intrusion in your sewer line, we can find your problem. Let the experts at Pipeliner Pros help you figure out which is the best long-term solution with a free video-inspection.

Tired of issues with your pipes? Frequent backups, slow drains, gurgling sounds, or foul odors could all point to a serious problem.

Locating and Mapping Services

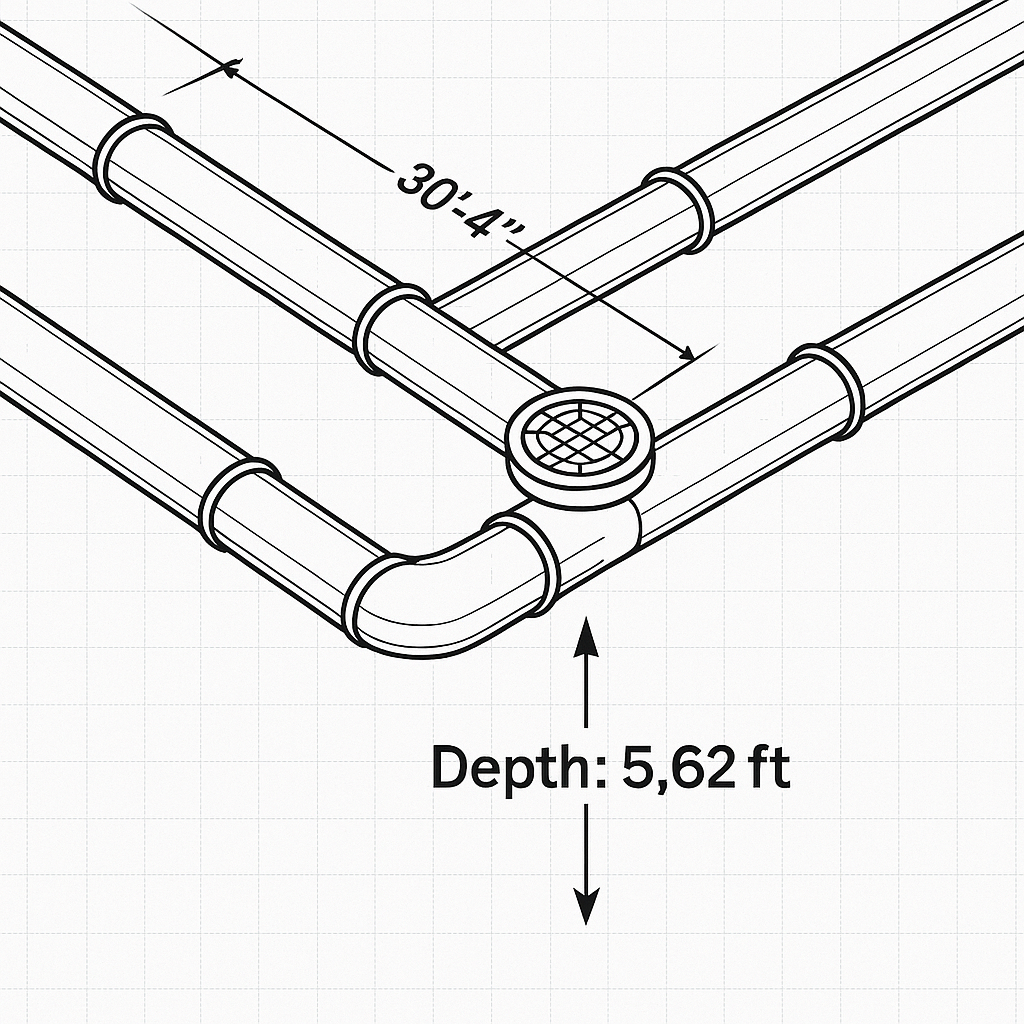

Accurate Pipeline Mapping for Future Reference

Knowing exactly where your underground sewer and drain lines run is critical for future maintenance, repairs, and renovations. Our professional locating and mapping services use advanced electromagnetic and sonde-based locating technology to trace and document the precise path of your pipelines—without any digging required. We provide you with a detailed layout of your system, including depth and direction, helping you avoid costly guesswork, unnecessary excavation, or accidental line damage down the road. Whether you’re planning a remodel, utility upgrade, or preventative maintenance, our mapping services give you the confidence to move forward with accurate, field-verified data.How Our Mapping Process Works

- Locate Pipelines: Pinpoint the exact location of underground or hidden pipelines.

- Map the System: Create a clear, detailed map for long-term use.

- Support Future Repairs: Provide accurate reference points to streamline future repairs and assessments.

Why Accurate Pipeline Mapping Matters

- Time Savings: Eliminate guesswork and locate pipelines quickly, reducing downtime and labor costs.

- Reduced Risk: Prevent accidental damage to underground utilities during construction, digging, or landscaping projects.

- Efficient Maintenance: Simplify future inspections and repairs with a detailed layout of your sewer and drain system.

Critical Severity Index (CSI) Modeling

Prioritize Repairs with Advanced Risk Assessment

Our Critical Severity Index (CSI) modeling uses patent-pending technology to evaluate the likelihood and consequences of pipeline failure. By combining real-world data with predictive analytics, this tool helps utilities and asset managers proactively plan repairs, reduce risk, and extend the lifespan of their infrastructure.

How CSI Modeling Helps

- Analyze Risks: Identify pipeline segments most likely to fail based on condition, flow data, and environmental stressors.

- Prioritize Repairs: Strategically focus on the most vulnerable or high-impact areas to maximize effectiveness.

- Prevent Failures: Address at-risk pipelines before they lead to catastrophic damage, service disruption, or regulatory violations.

Key Benefits of CSI Modeling

- Data-Driven Decisions: Make smarter maintenance and capital planning choices using accurate, objective data.

- Proactive Solutions: Reduce emergency response needs by planning ahead for potential failure points.

- Cost Efficiency: Lower lifecycle costs by directing resources where they’re needed most.