The Importance of Robust Sewer and Storm Pipelines for Industrial Applications

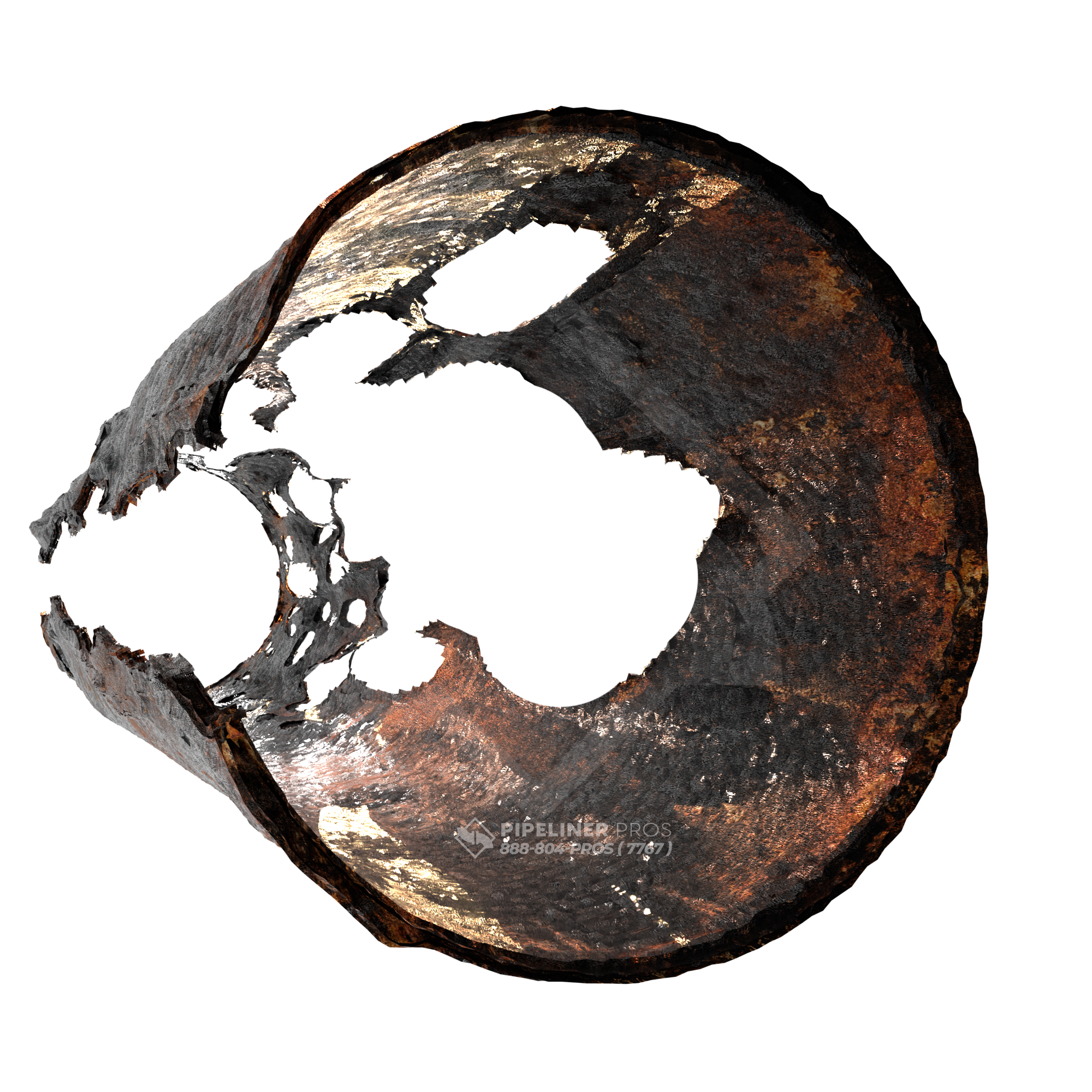

Industrial facilities depend on durable sewer and stormwater pipelines to manage wastewater, chemical runoff, and storm events effectively. These systems are vital for maintaining environmental compliance, operational continuity, and public safety. Over time, however, factors like chemical exposure, extreme temperatures, and aging infrastructure lead to deterioration and costly risks.

What can go wrong with industrial pipelines?- Operational Downtime: Pipeline failures can halt production and disrupt operations, leading to costly delays.

- Environmental Hazards: Leaks, infiltration, or exfiltration can cause contamination and regulatory violations.

- Safety Risks: Broken or collapsed lines can create dangerous working conditions or impact nearby communities.

- Financial Losses: Emergency repairs, environmental penalties, and non-compliance can lead to major unexpected expenses.

How Pipeliner Pros Solves Industrial Pipeline Challenges

We use advanced UV-cured CIPP (Cured-In-Place Pipe) lining technology designed to withstand the harshest industrial environments. Whether you’re dealing with failing storm lines, chemical drains, or deteriorated sewer systems, our trenchless UV CIPP solutions deliver long-lasting performance without disrupting your facility’s operations.

Types of Industrial Facilities We Service:

- Manufacturing Plants: Including food production, chemical processing, and metalworking facilities

- Logistics & Distribution Centers: Large-scale operations with complex underground systems

- Power Plants & Utilities: Including wastewater treatment and energy generation sites

- Pharmaceutical & Biotech Labs: High-purity environments requiring sanitary line integrity

- Oil, Gas & Petrochemical Facilities: Where enhanced chemical resistance is critical

Advantages of UV CIPP Technology for Industrial Use

- Customized Solutions: Tailored to pipe size, material, and layout—including difficult configurations and bends

- Fast, Non-Disruptive Installations: No shutdowns, no trenching—pipes are restored from the inside out

- Superior Chemical Resistance: Liners are engineered to resist industrial chemicals, oils, and high temperatures

- Cost-Effective Rehab: Avoids excavation, reduces labor, and extends pipeline life without full replacement

- Regulatory Compliance: Seals joints, stops infiltration/exfiltration, and prevents environmental violations

- Eco-Friendly Process: Less material waste, no major site disturbance, and zero landfill impact

- Improved Flow Efficiency: Smooth, seamless liners eliminate scaling, improving system performance

Why Industrial Facilities Choose Pipeliner Pros

Our team understands the complex needs of industrial environments—and the pressure to minimize downtime. We work directly with your engineers, facility managers, and EHS personnel to plan, phase, and execute trenchless repairs that maintain compliance and protect infrastructure investments.

- Custom-engineered trenchless solutions for industrial sewer and storm systems

- Rapid deployment and fast curing to limit facility disruption

- Resistant to acids, solvents, and industrial byproducts

- Budget-conscious approach without sacrificing durability

- Documented compliance with EPA, OSHA, and local standards

Contact us today to schedule a facility evaluation and learn how our UV CIPP solutions can extend the life of your industrial sewer and stormwater pipelines—without digging, downtime, or risk.

Case Studies Updating

Why Choose Pipeliner Pros for Industrial & Warehouse Pipe Repair?

Florida’s industrial warehouses, manufacturing plants, and logistics hubs face serious challenges from aging infrastructure—especially cast iron sewer lines, floor drains, and storm systems that run beneath concrete slabs or through structural foundations. Pipeliner Pros was built to restore these failing systems without disrupting operations or halting production. We work directly with plant engineers, facility managers, and safety officers to implement trenchless CIPP solutions that rebuild pipelines from within—no saw cutting, no excavation, and zero interference with equipment, inventory, or scheduled output. Our crews are experienced in working within active industrial environments, and every project is scoped and phased to maintain operational continuity, safety compliance, and minimal downtime. With decades of Florida-specific pipe rehab experience, we deliver industrial-grade results that last—not temporary fixes. Whether it’s a collapsed sewer line under a warehouse slab, a deteriorated storm drain at a loading dock, or corroded process drains in a manufacturing floor, Pipeliner Pros gets the job done efficiently, cleanly, and without costly disruption to your facility.Experienced Technicians

Our team is trained to handle all types of drain issues, from minor clogs to severe blockages.Advanced Drain Tools

We use state-of-the-art equipment to deliver efficient and lasting solutions.